New ERMAKSANN CNC HGD 3100-13 guillotine shear

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

plate thickness 13,0 mm

thickness at "Niro-steel" 8,0 mm

down holder 14 Stück

no. of strokes 11 Hub/min

oil volume 310 ltr.

cutting angle 2,0 °

throat 350 mm

table height 900 mm

total power requirement 22,0 kW

weight of the machine ca. 12200 kg

range L-W-H ca. 4100 x 2300 x 2235 mm

--------------------------------------------------

heavy electr. / hydraulic CNC swing cut shears

* with CYBELEC CNC touch screen control

* with electr. / hydr. Kerf adjustment

--------------------------------------------------

Furnishing:

- CNC electr. / hydraulic swing cut shears

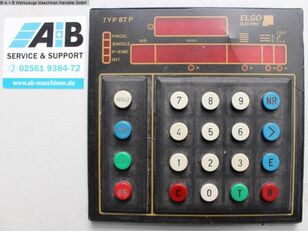

- CYBELEC CNC touch screen controller, model CybTouch 8

* Backgauge preselection - X axis

* Cutting gap adjustment

* Number of pieces

* Cutting length limitation

* Material preselection, including sheet thickness

* Cutting line lighting

- motorized backgauge, travel = 1,000 mm (X axis)

* on ball screws

* autom. Can be folded up at max.travel, for longer cuts

- 1x side stop

- 2x front support arms

- Ball casters in the front support table

- hinged finger protection, with safety switch

- BOSCH / HOERBIGER hydraulic system

- SIEMENS electrical system

- light barrier behind the machine (safety device)

- foot switch

- CE mark / declaration of conformity

- User manual: machine and control in German

The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

Hubzahl 11 Hub/min

Ausladung 350 mm

Gesamtleistungsbedarf 22,0 kW

Maschinengewicht ca, 12200 kg

Abmessung L-B-H ca. 4100 x 2300 x 2235 mm