Reifenhäuser BI Trudes 115 plastic extruder

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Additional equipment

2x electrical melt pressure transducer 1/2 “UNF diaphragm pressure transducer

2x ground temperature sensor with sword probe

Machine Benefits

Qualitative Machine Benefits

13x anchoring for one fixing point installation tool

Pair of worms, compact version, made of highly tempered steel and bimetal design

Counter-rotating twin-screw extruder, gearbox with integrated back pressure bearing for 350 bar

Recirculating oil lubrication with oil pressure and oil temperature monitoring

Barrel Ø 115-30 d with atmospheric and vacuum degassing openings

Heating and air cooling divided into 5 zones, total output of 56400 w

Vacuum unit for bt 115 including 2x vacuum unit and vacuum suction unit

Complete screw temperature control including cassette installation

Mains supply with main switch and load disconnector for heating, drives, and auxiliary voltages

Technical Machine Benefits

Stationary for an extrusion height of 1000 mm

Complete control cabinet with all necessary control and regulation equipment attached

Microprocessor-controlled multi-channel controller for two and three-point zones

Adaptive and self-optimizing control behavior

Fault messages with collective alarm and storage

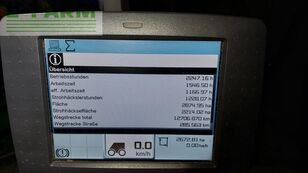

Siemens mp377 touch panel for setpoint specification and actual value display

Recipe management of up to 20 recipes

Drive with one ac motor, vector-controlled

Digital drive controller for ac motors, with full digital technology

Motor temperature monitoring with pre-warning and shutdown

Extra Information

Machine still under power

application type: Extrusion

Location: Germany

machine type: Pipe Extruder